Hall construction from A to Z

Added 04.05.2015- Processing of the plan for the construction of a prefabricated hall

- Before we start building

- Hall project

- Obtaining a building permit for the construction of the hall

- Realization of the hall

- Completion of the prefabricated hall

- Trial operation in the hall - guarantees

- Maintenance of the hall

- Archiving of documents

1. DRAFTING THE CONSTRUCTION PLAN for the prefabricated hall

Let us first clarify the ideas that lead us to the realization of the construction plan for the new building - the prefabricated hall.

- Do we necessarily need a new building, is there no other solution? Reconstruction, reorganization of processes, extension, extension, rental?

- Do we have the possibility to acquire suitable land or do we own it?

- Is this land included for the construction of the building - the hall, in the town or municipality's zoning plan?

- Does the site have any restrictions? Building height, size, noise, emissions, truck traffic, etc.?

- Does this land have connections to roads and utilities in the required dimension?

- Is there an assumption that all neighbors will agree to the development?

- Could the implemented project meet the criteria of any subsidy titles? E.g. for 2015 OPPIK - Operational Programme Enterprise and Innovation for Competitiveness, including sub-programmes innovation and energy savings.

2. BEFORE WE START BUILDING

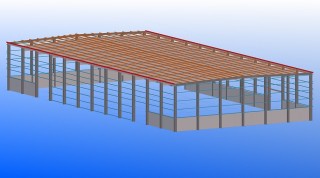

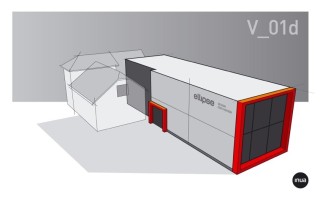

The location of a prefabricated hall on a plot of land is particularly important from three points of view: the functionality and serviceability of the hall, the aesthetic aspect and the slope - the nature of the terrain.

The geological survey will give us information about the possibility of establishing the hall and also about the hydrogeological conditions of the site.

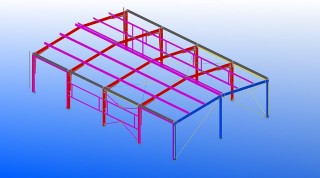

Based on the evaluation of the two previous points, we can start planning the actual building - the hall.The initial input information is mainly: the nature of the production - operation, the required height and width of the hall, the main material and transport flows, lifting and transport mechanisms, the dimensions of the required doors and gates and their connection to internal and external roads, a rough design of the natural lighting - windows, wall illumination, roof illumination, possibly ridge skylights.

After designing the dimensions of the building, we will consider and, if necessary, consult the shape of the hall or its extensions, the type of external and roof cladding, insulation and we will also focus on the colour design of the whole building. Colour solutions and contrasts in the colour of the walls, roof, windows and doors can greatly influence the overall impression of the building - the hall, and thus increase the "image" of the entire company towards clients - customers.

The last point of the pre-project preparation is a rough idea of the overall aesthetic completion of the newly built hall - the whole area by adding greenery, trees, sidewalks, parking lots, etc.

3. hall design

It is recommended to conduct an internal selection procedure for the designer of the building, where the main criteria may be quality, references, deadline for delivery of complete drawings and price.

To facilitate communication between the investor and the designer, it has proved useful to have a professional consultant to deal with professional and financial matters and to "watch" the designer to ensure that he works exclusively in the interest of the investor - the project sponsor. The consultant may also handle building permits and may act as the investor's construction supervisor during the construction process.

All known comments from previous meetings and plans shall be included in the hall design to ensure that the detailed design includes all parameters required by the investor - project sponsor.

The design documentation can be done in two levels - for the building permit and as detailed design documentation.

4. ISSUANCE OF BUILDING PERMIT for the construction of the hall

In connection with Act No. 350/2012 Coll., amending Act No. 183/2006 Coll., on spatial planning and building regulations (Building Act), as amended, and other related regulations, the Ministry of Regional Development in the field of spatial decision-making and building regulations proceeded to legislative amendments to the following implementing decrees:

- a/ Decree No. 499/2006 Coll., on documentation of buildings,

- b/ Decree No. 501/2006 Coll., on general requirements for land use, as amended,

- c/ Decree No. 503/2006 Coll., implementing certain provisions of the Building Act on zoning proceedings, public contract and zoning measure. The fundamental change brought about by the proposal is the extension of Decree No. 503/2006 Coll. by the entire content of Decree No. 526/2006 Coll., implementing certain provisions of the Building Act in matters of building regulations, including application forms. Decree No. 526/2006 Coll. is proposed for repeal at the same time.

When dealing with the building permit for the prefabricated hall, the changes in the above-mentioned regulations and decree must be respected and the time limit for the concerned authorities to comment on the applications, which is 30 days, must be kept in mind.

5. IMPLEMENTATION OF THE HALL

Once the approval of the local building authority has been obtained, the actual construction work for the steel hall can begin.

However, before the building permit is issued, preparatory work can be carried out - utility relocations (after approval by the owners and operators of the utilities) and rough landscaping. Sometimes the opinions of the building authorities on the extent of the preparatory work vary, so it is advisable to consult the locally and factually competent building authority in advance.

It is advisable to hire a construction supervisor to check the scope, quality and cost of the construction work, who will "keep an eye" on these matters and continuously check them, participate in inspection days, record the decisive facts in the construction diary, and confirm these facts if necessary. This includes, in particular, the handover of the site to the contractor, acceptance of the steel reinforcement in the concrete, acceptance of the completion of the construction units, or confirmation of justified extra work and its valuation, etc.

6. Completion of the prefabricated hall

During construction, the investor's construction supervisor (hereinafter referred to as TDI) collects documents from suppliers and contractors - certificates for the products and materials supplied and used, or declarations of conformity for foreign supplies. Attestations are also required, e.g. for scaffolding.

The TDI also takes copies of the construction diary, or logs if the construction diaries are kept separately by the individual contractors.

Prior to completion, the work previously carried out is also checked to ensure that there has been no change in the shape, texture or colour of the individual materials and structures. This takes advantage of the presence of the contractors on site to remedy any defects and deficiencies.

The financing of the construction of the hall is usually based on advances from the client to the contractor or contractors. The amount of advances should correspond approximately to the work carried out or the materials delivered.

The completed building is transferred to the client by handover, which is evidenced by a separate report signed by the contracting parties and the TDI.

After handing over the construction to the Client, the Client shall apply to the local competent building authority for the issue of the Approval Decision. Only after a valid Approval Decision has been issued, the client, now the owner of the work, can apply for registration in the Real Estate Cadastre.

7. Test operation in the hall - guarantees

During the trial operation and guarantee period, the work previously carried out in the hall is checked, similarly to the work carried out before completion, if there is no change in the shape, structure or colour of the individual materials and the construction carried out. The function of the heating and filter-ventilation system, the watertightness of the roof insulation, the tightness and function of the windows, doors and skylights, etc., shall also be checked.

8. Hall maintenance - washing and cleaning of steel halls

-

Wall cladding

Washing and maintenance of all types of external building envelopes can be carried out using ladders and platforms as standard, and in exposed cases also using climbing equipment.

The actual cleaning is carried out with a high-pressure cleaning unit, e.g. by KARCHER, where high quality can be achieved by correct adjustment of the temperature and water flow, the nozzle used and additional devices. In the case of heavy pollution, chemical products can be used which are naturally degradable and therefore do not risk polluting the environment. Nevertheless, chemical products are used only to a minimum extent. Logically, washing and cleaning is carried out from top to bottom so that the dirty water flows downwards. The slope of the nozzle must always be directed in such a way that it does not run into windows or wall cladding. This is especially true for cassette cladding and panel cladding placed horizontally.

-

Hall roof

Roof sheathing on steel halls is usually made either of panels filled with polyurethane foam or as a classic stacked sandwich with mineral wool. The top sheet is made up of trapezoidal profiles or profiles imitating classic clay roofing of various colours and shapes. The renowned manufacturer and our supplier of RUUKKI roof panels and sheets, made of high-quality Finnish steel, coated, which provides a technical warranty of 30 - 50 years for its products, recommends the following maintenance procedure for roofing and guttering:

Immediately after installation of the roof cladding, all loose objects such as excess fasteners, pieces of roofing material, chips and splinters from drilling and other metal particles should be removed from the roof and gutter systems.

To ensure optimum functionality and longevity of the roof, you should regularly inspect the condition of the roof. If you find any damage to the finish, you should repair it immediately. This will ensure the longevity of your roof.

Usually, snow will not stick to the roof and its weight will not exceed the load capacity of the roof. However, if it is necessary to remove the snow from the roof, it is recommended to leave a layer of approximately 100 mm on the roof to prevent damage to the roof when removing the snow.

Visual inspection of panels and roof sheets

A visual inspection of the surfaces is normally carried out every year as part of the routine inspection. A thorough inspection should then be carried out every 5 years after installation of the roof sheathing. Thereafter, it is optimal to inspect the roof surface every two years at the latest.

Inspection of screws and fasteners

Check that all fasteners are held in place and are not corroded. Damaged or loose fasteners can cause water leakage, corrosion or even deformation of the structure. If a joint is damaged, it must be repaired immediately or replaced with a stronger joint.

Check the surface finish

The surface finish is checked for colour fastness and the overall surface of the roof cladding. The roof gutter and edges of the eaves systems must also be checked. Bubbles, flaking of the finish, inconsistent fading of the paint, and cracks or scratches indicate that the finish is in dire need of professional repair.

Cleaning of gutter systems

The cleaning interval for prefabricated shed gutter systems is generally one year. If there is a risk of leaf and debris infestation, it is recommended to check twice a year - always before and after winter. Clogged or only heavily soiled gutter systems can hold increased moisture and therefore corrode or freeze.

The rain will usually take care of keeping the painted roofing and guttering clean as normal. However, mechanical debris such as leaves, dust, ash, moss, should be mechanically removed from the roof, gutters and gutter systems once a year.

Cleaning the roof of the prefabricated hall

Corrosion occurs where there is dirt and moisture, as the surface under the dirt is always damp. A dirty hall roof also spoils the visual impression and image of the company.

To clean the finish, it is advisable to use a soft brush and water or pressurised water. Resistant dirt is removed using a cleaning agent suitable for the surface with the given colour finish.

Please note that inappropriate or harsh cleaning agents can damage not only the paint finish but also the steel plate.

Paint repairs and gutter maintenance

We also repair small scratches and damage. Even small defects can result in major damage or corrosion. When making repairs, it is essential to use only paints appropriate to the specific finish being repaired.

When repairs are done by hand, we use the smallest brush possible. If one coat of paint is damaged, one coat of paint will also suffice. If the damage is deeper - extending to the zinc layer, it is necessary to apply two coats of paint. The second coat is applied after the first coat has dried properly.

Corrosion may occur in the folds and on the edges of the gutters. This is more common on low-slope roofs. You can prevent corrosion from occurring by painting the edges of the eaves after the roof has been installed. For this reason, it is also forbidden to cut or cut sheet metal parts by grinding with cutting wheels. Grinding galvanized and painted sheet metal can create galvanic cells that lead to edge corrosion over time. For this reason, sheet metal is cut.

Repainting of the roof finish

If you are considering recoating the entire roof surface, you must first check that the shed roof and its supporting structure is not seriously damaged in any place and that the original coating on the base course is holding up well. If significant damage is found or if the finish is irregularly mottled or faded, consult a professional about the whole process and together suggest the most appropriate and effective course of action to implement the coating renewal plan.

The end-of-life of the coating, i.e. the time when a new coating should be applied to the roof, cannot be exhaustively determined as it is influenced by many factors. It is the colour and type of coating itself, the altitude - weathering, the shape and pitch of the roof, the method of construction and installation. Finishes on the sunny south side of the roof have the worst conditions, especially if the roof of the hall is dark in colour.

9. Document archiving

In accordance with the provisions of Section 125 of the Building Code, the builder is obliged to keep the project documentation of the actual design of the prefabricated hall for the entire duration of the construction. Further copies of the project documentation shall be kept in the archives of the relevant building authority and, where appropriate, the relevant municipality.

From a practical point of view, attention should also be paid to the completeness of the archived documentation, not only the construction design - floor plans, sections and geometric surveys. Very important is also the actual design and measurement of utilities, but also the internal distribution of energy, gas, water and sewage. Accurate archiving of complete projects and documents will avoid many problems that may arise many years from now.